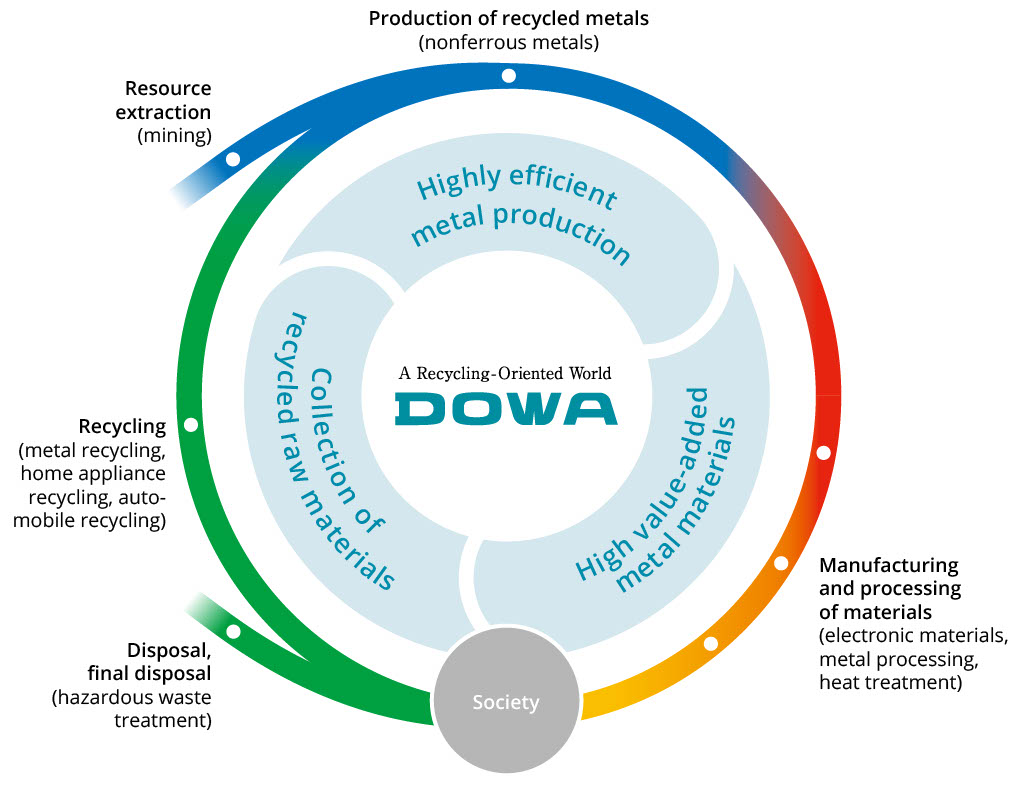

The global shift towards a resource-recycling society is accelerating, and demand for recycling is growing. Achieving a circular economy and a decarbonized society requires global resource recycling. The DOWA Group is developing its unique recycling-oriented business model, focused on metals, to reduce the consumption of natural resources and promote the recycling of used resources, aiming to build a sustainable world.

Our Group has built a recycling-oriented business model that realizes a cycle from the collection of recycled raw materials to the efficient production of metals and the enhancement of their value. In the Environmental Management & Recycling Business, we detoxify waste and recycle metals from used products, utilizing the recycled metals as raw materials for smelting. The Nonferrous Metals Business produces recycled metals from a variety of recyclable materials, in addition to ores, which are natural resources.

These metals undergo various processes such as purification, plating and surface treatment in the Electronic Materials Business, Metal Processing Business, and Heat Treatment Business, gaining added functional value before being incorporated into automobiles and electronic devices. Products, once they pass from manufacturers to consumers and eventually reach the end of their use, are collected again as recycled raw materials by the Environmental Management & Recycling Business, creating a resource recycling network.

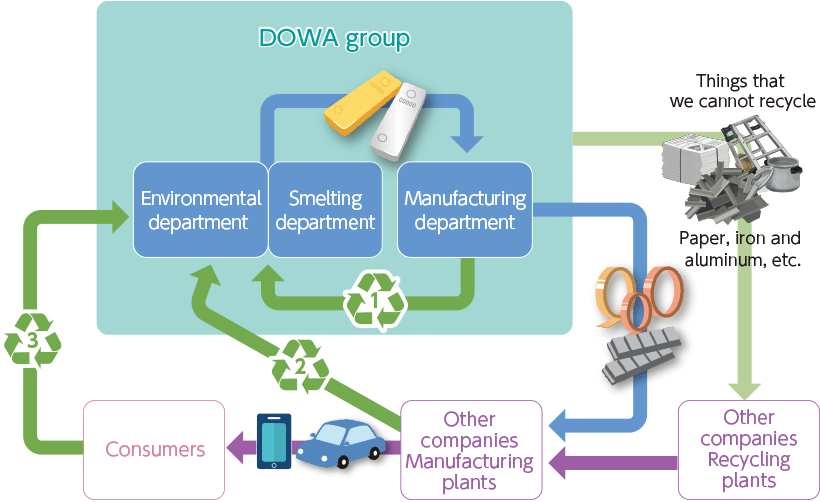

At the DOWA Group we are working on effective utilization of limited resources through the three loops of our own manufacturing process, the manufacturing processes of other companies, and the waste generated by society. At the same time, as a social responsibility in resource recycling, together with striving to minimize the environmental impact at every stage of recycling, such as appropriate water treatment, detoxifying waste and reliable landfill, we are aiming for sustainable resource recycling that considers environmental conservation and energy savings, such as using heat generated in the treatment process as steam or electric power.

- With in-house generation and usage, for waste generated in the” manufacturing business”, such as our smelting and metal processing, it is recycled in the “environmental business” and “nonferrous metals business”. Besides selling it as metallic material, we re-use it as raw material for our company.

- Accepting and recycling scrap metal generated from the processes of manufacturing plants at other companies. In case it is from client factories that supply our materials or par ts, such thin gs as reusing theaccepted waste as raw material leads to a reduction of new resource inputs.

- Recycling of used end products. Through electrical appliance recycling, automobile recycling and the recycling of small household appliances, used products widely recovered from society will be returned to society as metallic material again.

Centered on Kosaka Smelting & Refining Co., Ltd., a smelting and recycling facility, we are working to further strengthen our unique recycling-oriented business model, which combines our environmental business with the smelting of recycled materials. Our intention is to increase the amount of metals derived from recycling that are used in production through collaboration between the Environmental Management & Recycling Business and the Nonferrous Metals Business. To this end, we are moving forward with efforts that include expanding the collection of recycled raw materials, upgrading equipment at each plan, and increasing the types of metals we can recover.

The integration of the Environmental Management & Recycling Business and the Nonferrous Metals Business is a crucial step toward more robust resource recycling. Therefore, we are planning to enhance the pretreatment function of the Environmental Management & Recycling Business, which will allow us to ramp up the collection and treatment of recycled raw materials. In the Nonferrous Metals Business, we will raise efficiency by upgrading equipment, which will allow us to recover a greater range of metals.

We believe that SDG 12, calling for “sustainable consumption and production patterns,” holds the greatest relevance to DOWA, which thrives on the utilization of metal resources, an area where we can make a massive contribution. As put forth in our Corporate Mission, we aim to achieve SDG 12 by putting our technologies and resources toward building a recycling-oriented society.

|

Key Measures |

Indicators |

Targets |

|

Increase collection of recycled raw materials |

Volume of recycled raw materials collected by Kosaka Smelting & Refining (FY2021 = 100) |

110 (FY2024) |

|

Volume of spent catalysts from automobile exhaust purification collected (FY2021 = 100) |

140 (FY2024) |

|

|

Volume of recycled for used Lithium-Ion Batteries (FY2021 = 100) |

400 (FY2024) |

|

|

Increase ratio of metals derived from recycled raw materials |

Ratio of metals derived from recycling that are used in production (based on sales in the Nonferrous Metals Business)* |

70% (FY2024) |

*”Recycled raw materials” includes secondary smelting raw materials other than recycled raw materials for Kosaka Smelting & Refining

In our Group’s Midterm Plan 2024, we are working to increase the proportion of metals produced from recycled raw materials (based on the sales of the Nonferrous Metals Business). In fiscal 2023, the proportion of metals derived from recycled raw materials was 58%, a 1-point decrease from fiscal 2022. This decrease was mainly due to the drop in platinum group metal prices, which led recyclers handling spent exhaust gas purification catalysts to withhold shipments, resulting in a reduction in the collection of recyclable raw materials compared to fiscal 2022.

Recycling is one possible way to promote effective resource use. However, this requires technology to recover metals efficiently as well as the technology and infrastructure for safely processing harmful and non-harmful substances generated in the recycling process. Recycling also brings with it other technological and economic issues that must be addressed, such as the need to create an efficient collection system for recycling raw materials and a means for addressing the labor requirements and costs associated with processing this wide variety of raw materials. Bearing this in mind, the DOWA Group is working to promote the sustainable use of metal resources while taking on the various challenges present in resource recycling.

Lithium-ion batteries (LIBs) have broad applications, ranging from mobile phones to electric vehicles, with demand on the rise. However, when these batteries are discarded or dismantled, they pose the risk of electric shock or fire, and the value of the metals that can be recovered from spent batteries is subject to market prices. For these reasons, a treatment method that is not only stable but can be continued over the long term has yet to be developed. It is our hope that we will be able to develop a safe and efficient system to manage the large volume of batteries that will be produced in the future. Our Group is further strengthening the competitiveness of our recycling processes and technologies to reliably meet the demand during this market formation phase.

Our Group recycles spent lithium-ion batteries at Eco-System Akita (Odate City, Akita Prefecture) and Eco-System Sanyo (Kume District, Okayama prefecture).

Furthermore, DOWA Eco-System, which leads our Environmental Management & Recycling Business, has participated in the joint lithium-battery collection scheme organized by the Japan Automobile Manufacturers Association (JAMA) since October 2018. Both Eco-System Akia and Eco-System Sanyo are registered as battery recycling facilities under this program.

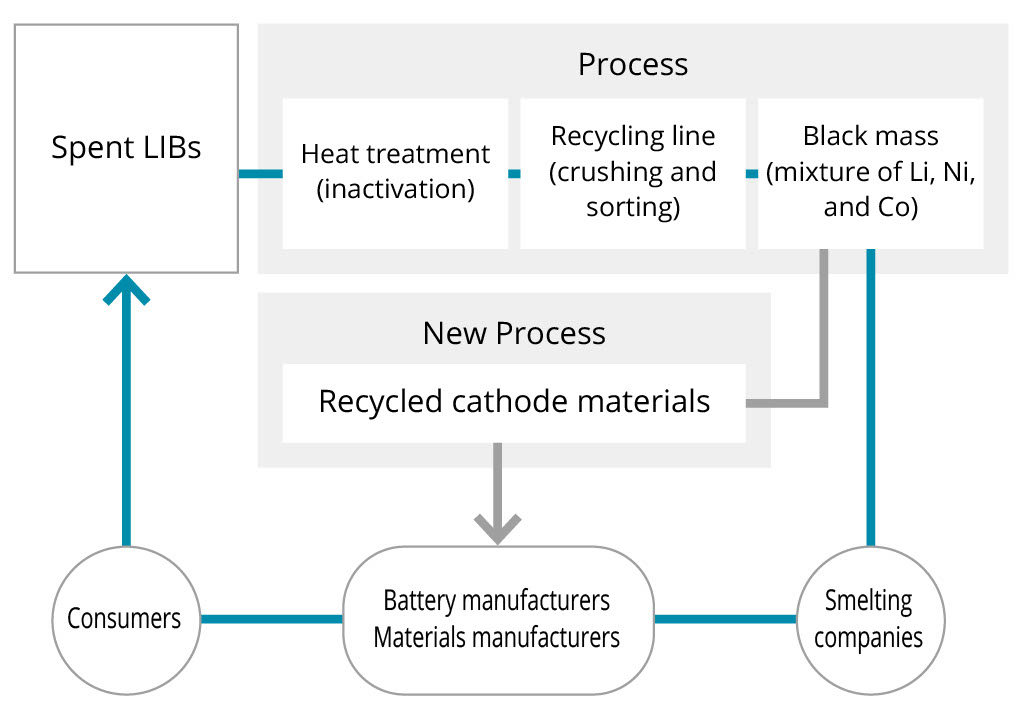

In November 2022, we successfully recycled cathode materials from spent automotive lithium-ion batteries after heat treatment through joint research with Akita University. In this process, we recovered cathode material components (black mass), which contained a certain amount of impurities, from the deactivated spent lithiumion batteries after heat treatment and reused them to manufacture new cathode materials. As a result, we were able to attain similar electrochemical performance to automotive LIBs on the market in electricity storage capacity and charge-discharge cycling stability. Moving forward, we are targeting on developing a process to control impurity content more efficiently while learning more about the relationship between the nature of cathode impurities and battery performance in detail.

The DOWA Group operates a broad range of recycling businesses that deal with precious metals; home appliances, including discarded small household appliances; and automobiles. These businesses do not simply carry out recycling in isolation. Instead, we improve resource efficiency through a systematic treatment process that accounts for the specific characteristics of a facility in terms of technology as well as the geography and related circumstances of where that facility is located. The Group’s operating companies also collaborate with research laboratories and other departments involved in transport, analysis, and various other related areas of operation to utilize resources effectively. When necessary, the Group also works with outside sectors and partners in order to optimize the value chain. For example, we collaborate with steel manufacturers to recover metal from steel dust (secondary zinc raw material) and promote recycling of zinc using secondary raw materials.

One notable characteristic of DOWA’s business model is that it incorporates waste treatment in addition to recycling. Although we have devoted many years to improving our recycling technology and have worked to recycle increasing amounts of metals, there is some waste that cannot be recycled or reused with today’s technological capabilities. Since we possess facilities that are capable of properly treating and managing this waste, we are a vital link within the value chain that allows for greater resource efficiency, environmental conservation, and safety.

Our Group is advancing verification based on UL2809, a standard for evaluating and verifying recycled raw materials used in products. Products that pass the UL2809 verification are objectively evaluated based on their recycling process, serving as a reliable indicator for those seeking to purchase trusted recycled materials.

In August 2023, Eco-System Recycling Co., Ltd. (Honjo City, Saitama Prefecture) completed the UL2809 verification for potassium gold cyanide. This was followed by the verification of conductive atomized powder produced by DOWA ELECTRONICS MATERIALS OKAYAMA CO., LTD. (Okayama City, Okayama Prefecture) in March 2024, and in August 2024, verification was completed for the copper rolled products (Y-CuT FX) manufactured by DOWA METANIX CO., LTD. (Iwata City, Shizuoka Prefecture). These products have traditionally used 100% recycled meals sourced from scrap as raw materials. In response to the growing awareness of the SDGs and the push for more diverse recycling products and services, environmental label verification based on UL2809 was conducted for these products, confirming the validity of their 100% recycled material usage. Our Group will continue to expand the use of recycled raw materials in metal products to contribute to the creation of a sustainable world.

To promote sustainable resource use on a global scale, it is also necessary to reduce environmental impact, maximize resource efficiency, and collaborate across national borders. Conscious of that, we utilize our unique set of resources, which includes recycling technology, infrastructure, knowledge, experience, and human resources, to develop metal recycling and waste treatment businesses not only in Japan but also in China, Singapore, Thailand, Indonesia, and Myanmar. In addition, in North America and Europe, which are our main sources of recycled raw materials, we collect these materials via our sales and sampling bases and recover rare metals at domestic smelters. Through these and other efforts, we have built a resource recycling system that is not only global but promotes environmental conservation.

For many years we have worked on improving recycling technology and are working on building a recycling-oriented society through the recycling of metals. However, in reality, there is waste that cannot be reused or recycled. Waste incineration facilities and final disposallandfill sites tend to be kept at a distance, but if they cannot be built, there is no place for the waste to go, and public health could not be guaranteed. We believe that our waste disposaltreatment business, which develops technically safe facilities, performs appropriate maintenance and sufficiently communicates with residents, plays an important role for society.

The landfill site is a facility that supports the foundation of resource recycling. The DOWA Group will continue to develop landfill sites that are necessary for society by enhancing waste disposal treatment technology and reliably ensuring their safety and security.

The DOWA Group is participating in the Circular Partnership, which was launched to realize a circular economy based on the “Growth-Oriented Resource Autonomous Economy Strategy” of the Ministry of Economy, Trade and Industry. The Partnership will organically link organizations that are actively engaged in the circular economy, such as the national government, local governments, universities, and business and industry associations, and will study the measures that are necessary to realize the circular economy. Through these activities, we will collaborate with our partners and contribute to the realization of a circular society.

As market needs for waste treatment and resource recycling diversify, we are strengthening collaboration both within and outside the Company in the resource recycling supply chain. In the lithium-ion battery recycling business, we signed a partnership agreement with Sumitomo Metal Mining Co., Ltd. in March 2024 to build a supply chain for recycling spent lithium-ion batteries.

By leveraging our technology and expertise—which minimize the risks of electric shock and ignition, destroy the energy storage function through heat treatment, and render organic solvents in the electrolyte harmless—we will contribute to establishing an efficient recycling flow.