Every year, the DOWA Group confirms the status of water intake sources and drainage destinations in addition to water usage at production sites in Japan and overseas. In addition to working to conserve water at all business sites, we are promoting water recycling within processes to reduce the amount of water we withdraw. The entire Group is working to make effective use of water resources.

The largest use of water resources within the Group is as cooling water for the Nonferrous Metals Business, for which we use seawater. After use in the cooling process, the quality of the water is checked, and all of it, except for the water that had evaporated, is returned to the ocean from which it originated. Additionally, each business site is taking measures to protect water quality, not only by properly managing wastewater and complying with wastewater regulations, but also by setting strict voluntary standards.

52 of the Group's major production sites, accounting for approximately 75% of the Group's total, have acquired ISO 14001 or Eco Action 21 certification and have established an environmental management system (EMS) system for environmental management. In accordance with the Water Pollution Control Law and other environmental laws and regulations, we have established environmental plans including water management. We monitor the amount of wastewater taken and recycled, and work to properly manage water resources and reduce environmental impact.

The entire Group is working to reduce water withdrawal by recycling water used in the production process, utilizing rainwater, and thoroughly conserving water.

(Unit : m3)

|

Initiatives |

Reduction Amount |

|

Reduction through process efficiency improvement by installing equipment, etc. |

9,385 |

|

Reduction through cascading and reclaimed use of water in production processes |

51,312 |

|

Reduction through the use of rainwater in environmental measures |

11 |

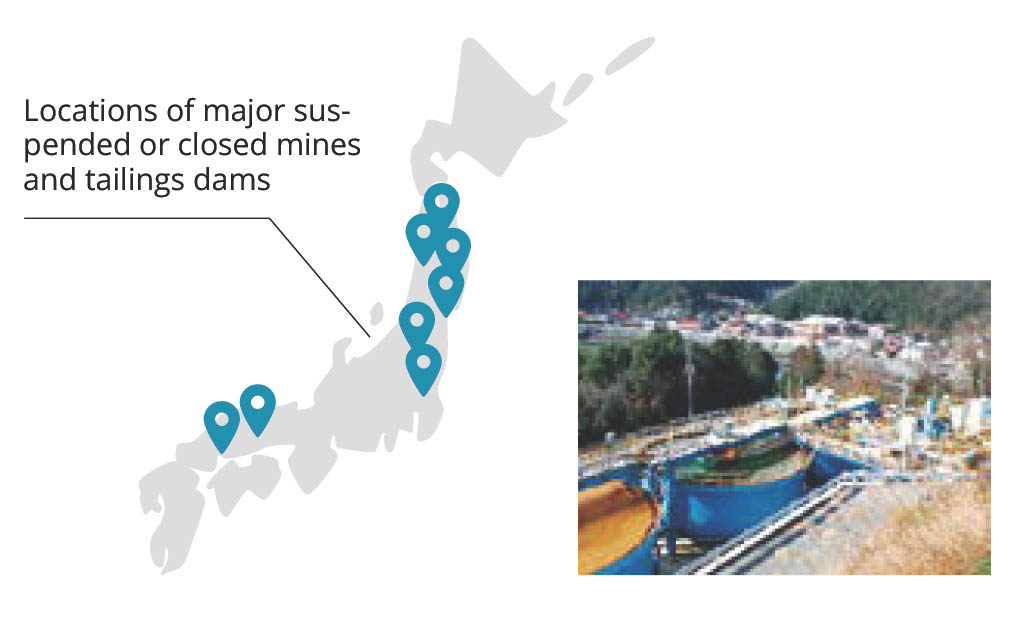

Mines can have a significant impact on the natural environment, including ecosystems and water, and on local communities. Because of this, it is the responsibility of operators to continue to carry out maintenance and management even after the mine is closed and to strive to prevent mine pollution.

At abandoned mines (mines that are currently out of operation or closed), there is a risk that acidic water or mine water containing heavy metals may leak out from the minehead, causing a deterioration of water quality and contamination of agricultural land. The DOWA Group currently operates and manages more than 20 abandoned mines and more than 30 tailings dams. We are working to maintain a healthy water cycle and a sustainable water usage environment. We have established voluntary management standards that are stricter than the mining laws and regulations, and monitor mine water and wastewater generated from mine tunnels and tailings dams 24 hours a day, 365 days a year, treating the water appropriately according to its properties.

At suspended or closed mines, mine water, including acidic water or water containing heavy metals, may flow out of the pithead; thus, there is the risk of wastewater flowing into rivers and harming water quality and agricultural land. Accordingly, we have established voluntary management standards that are stricter than mining laws and regulations for the suspended or closed mines and tailing dams that we currently operate. By doing so, the DOWA Group is working to maintain healthy water circulation and an environment conducive to sustainable water use.

Mine wastewater treatment plants and tailing dam facilities are inspected on an irregular basis by public safety and inspection departments in each region. All of the closed mines and tailings dams operated and managed by us are managed by wastewater treatment and other means based on voluntary management standards that are stricter than mining laws and systems. In addition, rehabilitation of closed mines and tailings dams that have ceased operations has been completed, including soil covering, pollution prevention work, and revegetation with vegetation, to maintain stable conditions. We set the items for inspection and the frequency thereof by location, including tailing dams still in use, with qualified people doing patrol inspections of such things as blocked pitheads, and we check the slopes and culverts of tailing dams in order to quickly detect and repair points of deterioration and keep conditions stable.