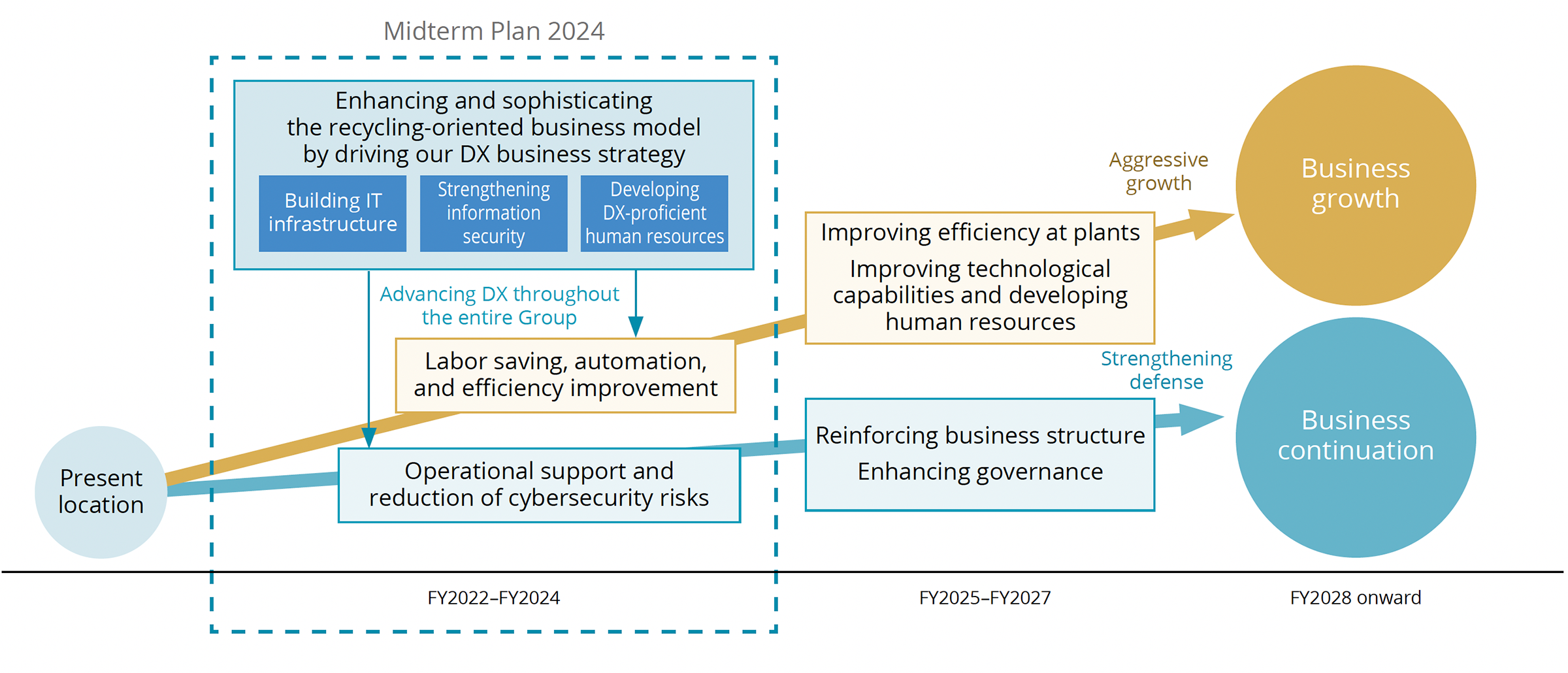

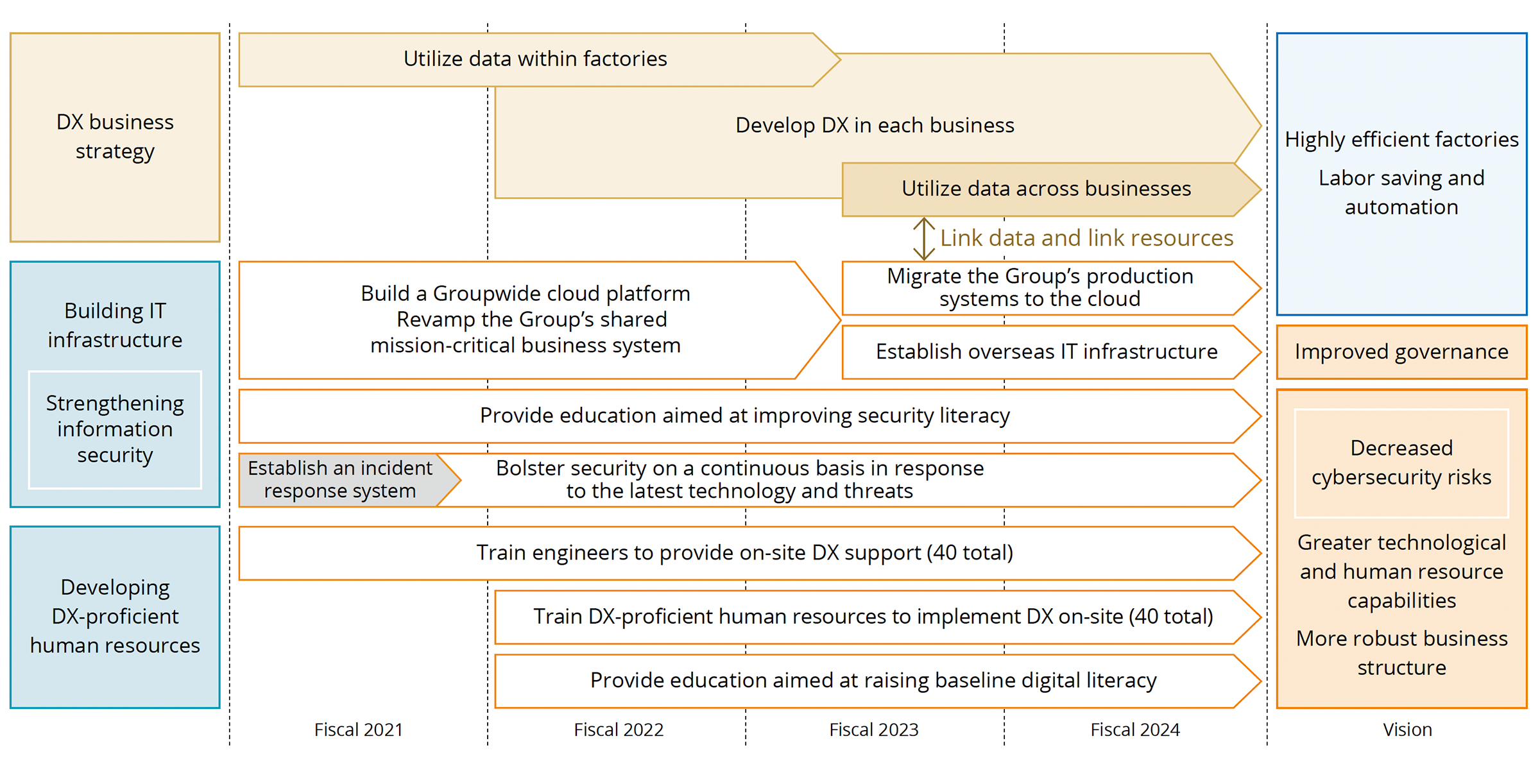

The DOWA Group recognizes that it is essential to promote data utilization through the use of digital technologies, including artificial intelligence (AI) and the Internet of Things (IoT), to transform manufacturing, the foundation of the DOWA Group’s business, and to evolve its operations and business activities. Based on this recognition, we have established a DX Basic Policy called Manufacturing Transformation (DOWA Transformation). We will promote DX by building IT infrastructure, strengthening information security, and developing DX-proficient human resources.

The Group formed a project team to promote digital transformation (DX) in FY 2021, and has been proceeding with Groupwide efforts to prepare for the promotion of DX. In April 2022, we formed the DX Promotion Working Group under the Sustainability Subcommittee. The DX Promotion Working Group sets targets for AI, the IoT, and other DX-related improvements; checks the needs, issues, and progress of DX projects underway at each operating site; and offers support by providing resources and through other means.

To transform operations, organizations, and processes across the Group by leveraging data and digital technology, it is essential to use a secure IT infrastructure managed by personnel with specialized knowledge and skills to advance business strategies. Therefore, in the Midterm Plan 2024, we are focusing on three key initiatives: IT infrastructure development, strengthening information security, and DX human resource development, to promote various activities.

|

Key Measures |

Indicators |

Targets |

|

Build IT infrastructure |

Operation of a group-wide cloud platform |

Start operation in the second half of FY2023 |

|

Develop DX-proficient human resources |

Number of personnel trained |

80 in total (FY2022 to FY2024) |

To meet the diverse needs for automation, efficiency, and labor-saving in offices and plants, a wide range of systems utilizing various digital technologies is required. As a result, in fiscal 2021, we began building a new IT platform (Groupwide cloud platform) to be used across the entire Group, and it became operational in August 2023. This has established a framework for the full-scale deployment of DX.

We are planning the migration of plant-specific production management systems to the cloud platform and the development of IT infrastructure at overseas locations. This will enable data integration and sharing across businesses and locations, such as real-time information sharing between the Environmental Management & Recycling Business and the Nonferrous Metals Business—an effort that previously required significant time and labor with traditional IT systems.

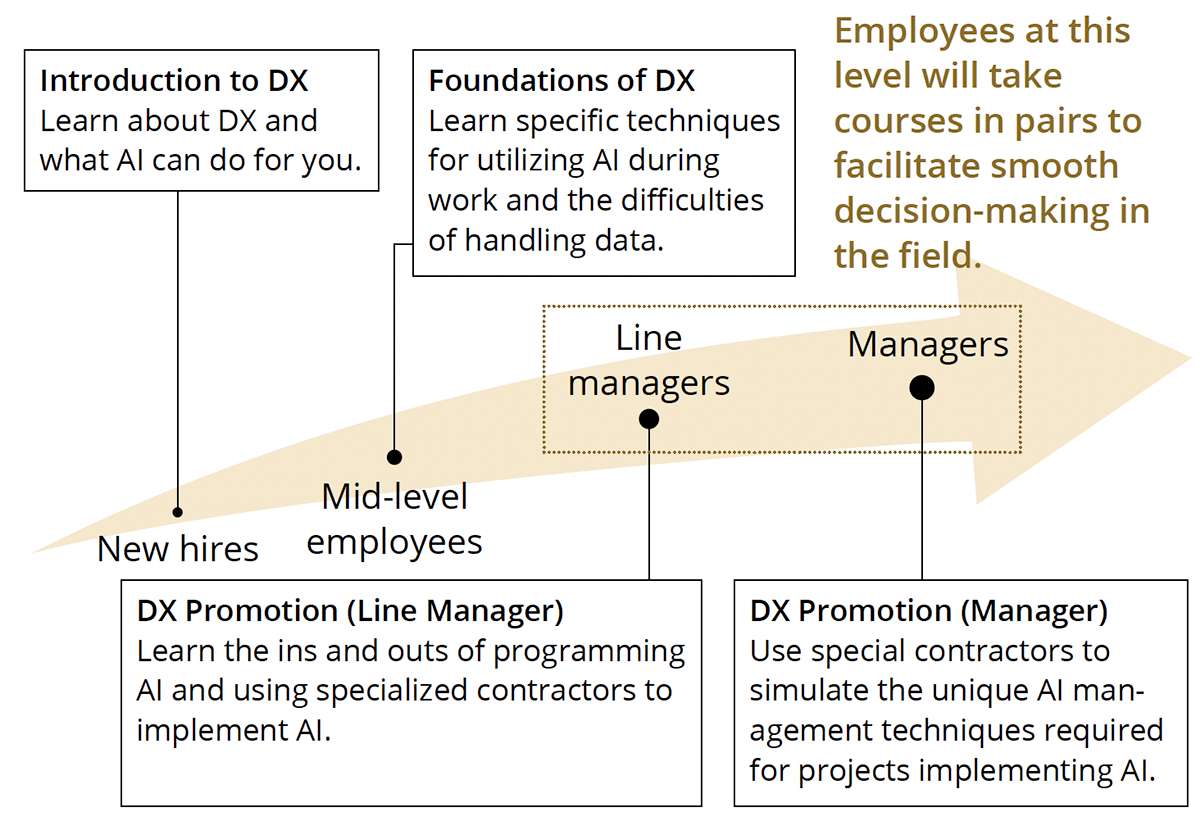

DX promotion requires human resources who can utilize digital technology at each business location. To this end, the Group is working to develop human resources capable of promoting DX within the Company. In particular, we have prepared a course that allows employees to learn more about AI, which can easily lead to on-site improvements in stages according to their development stage. We began training in the second half of FY 2022.

In the Midterm Plan 2024, we set a goal of training a total of 80 DX personnel over the three years from fiscal 2022 to fiscal 2024. In fiscal 2023, we trained 54 individuals, exceeding the planned number, following last year’s efforts. As a result, over the two years from fiscal 2022, we have successfully trained 121 individuals, surpassing the target.

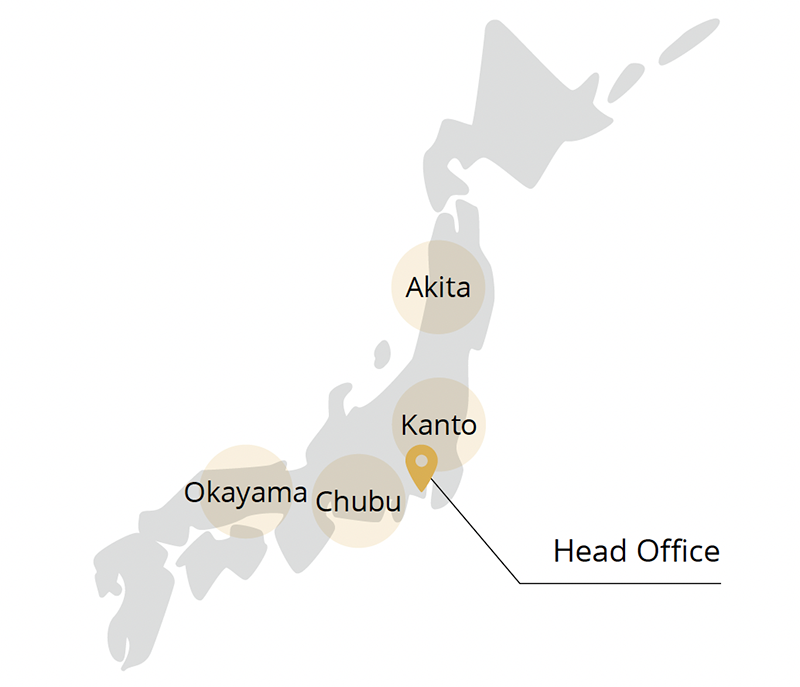

To promote DX at each of the Group’s bases, major domestic bases have established support centers for production technology and information systems (Akita, Kanto, Chubu, Okayama). Each support center supports various AI-related improvements (image analysis, acoustic analysis, data science, natural language processing), conducts surveys of each company’s situation regarding cloud utilization and information security, and makes proposals to meet their needs.

To protect IT infrastructure from ever-changing cyber-attacks, we incorporate the latest technologies to (1) never bring threats in, (2) prevent invasions, and (3) prevent the spread of threats. We sequentially deploy these technologies in the Company-wide network and plant networks. In addition, in anticipation of the growing business risks posed by cyber-attacks, we began cyber incident response training at our major sites in 2023. On the other hand, it is also essential for the Group’s employees to deepen their understanding of security, including the dangers of cyber-attacks and emails ridden with viruses, before going about their daily work to strengthen security. To this end, materials and videos explaining the fundamentals of information security that everyone should know, such as ransomware and business email fraud, in an easy-to-understand manner are available on the company intranet. They are also disseminated to overseas offices to improve information literacy among employees.

Efforts are underway to effectively integrate the vast operational data held by each plant and use data science to improve operations. In addition to keeping these initiatives within each factory, we are focusing on utilizing them as shared knowledge across the Group.

Examples of Data Science Utilization

- Identifying operational factors affecting product quality

- Preventing accidents and disasters through image detection

- using AI

- Optimizing operational conditions using AI algorithms

Generative AI, such as ChatGPT, has the potential to greatly transform how we conduct our work, but various risks such as information leaks and copyright infringement have also been pointed out. Therefore, to achieve the expected results from using generative AI in the workplace, it is crucial to fully understand its characteristics and use it correctly.

From fiscal 2024, our Group has launched the operation of the DOWA version of a general-purpose generative AI to improve the quality and productivity of our work. In conjunction with this, we established the DOWA Group Generative AI Usage Guidelines to ensure safe and appropriate use of generative AI. These guidelines clarify the unified rules for using generative AI and aims to ensure that it is used correctly.

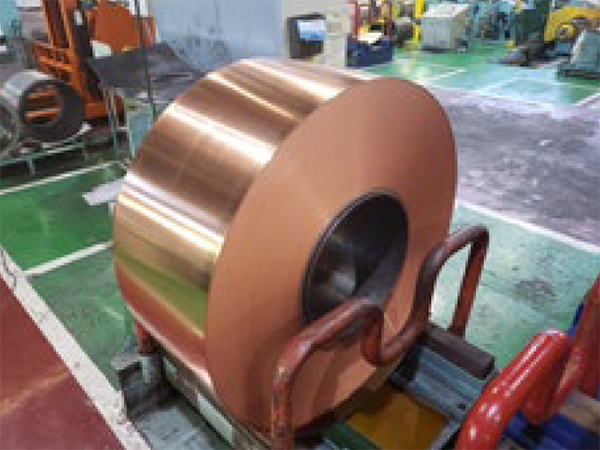

DOWA METANIX CO., LTD. manufactured copper rolled products. Since copper rolled products must be free of surface defects, automatic image-based inspection is used to detect defects. However, conventional image inspection cannot distinguish defective images that lead to serious quality anomalies from others, so human operators ultimately reconfirm many images. Aiming to improve productivity, we have now built a system that reads existing defect images and outputs the classified results using AI technology. As a result, the number of images requiring reconfirmation by human operators was reduced by approximately 97%. In addition, the Company has achieved a 100% reproducibility rate of defect classification using AI technology while achieving zero missed critical defects as we have in the past. These efforts were made possible with internal resources, including using an internal cloud. In addition, by enhancing the user interface and other aspects of the system, we were able to build a system free of mystery that is easy for operators to use.

- 拡大

- AI-based Detection of Surface Defects in Copper Rolled Products

In July 2022, the Company was recognized as a DX-certified operator by the Ministry of Economy, Trade and Industry. The DX Certification initiative is a government-sponsored initiative that grants certification to businesses ready to promote DX in accordance with the requirements specified in the Digital Governance Code formulated by the Ministry of Economy, Trade and Industry.